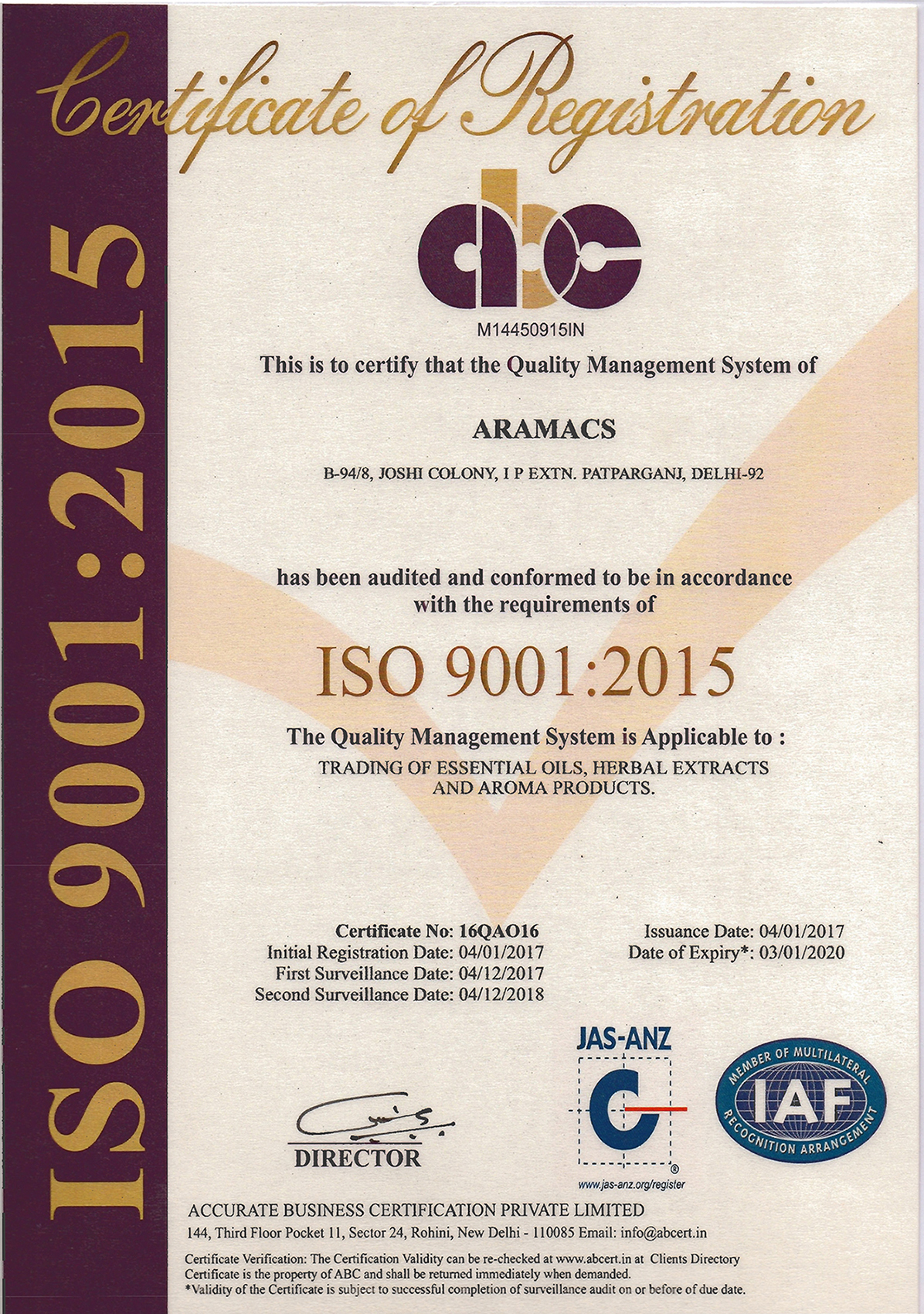

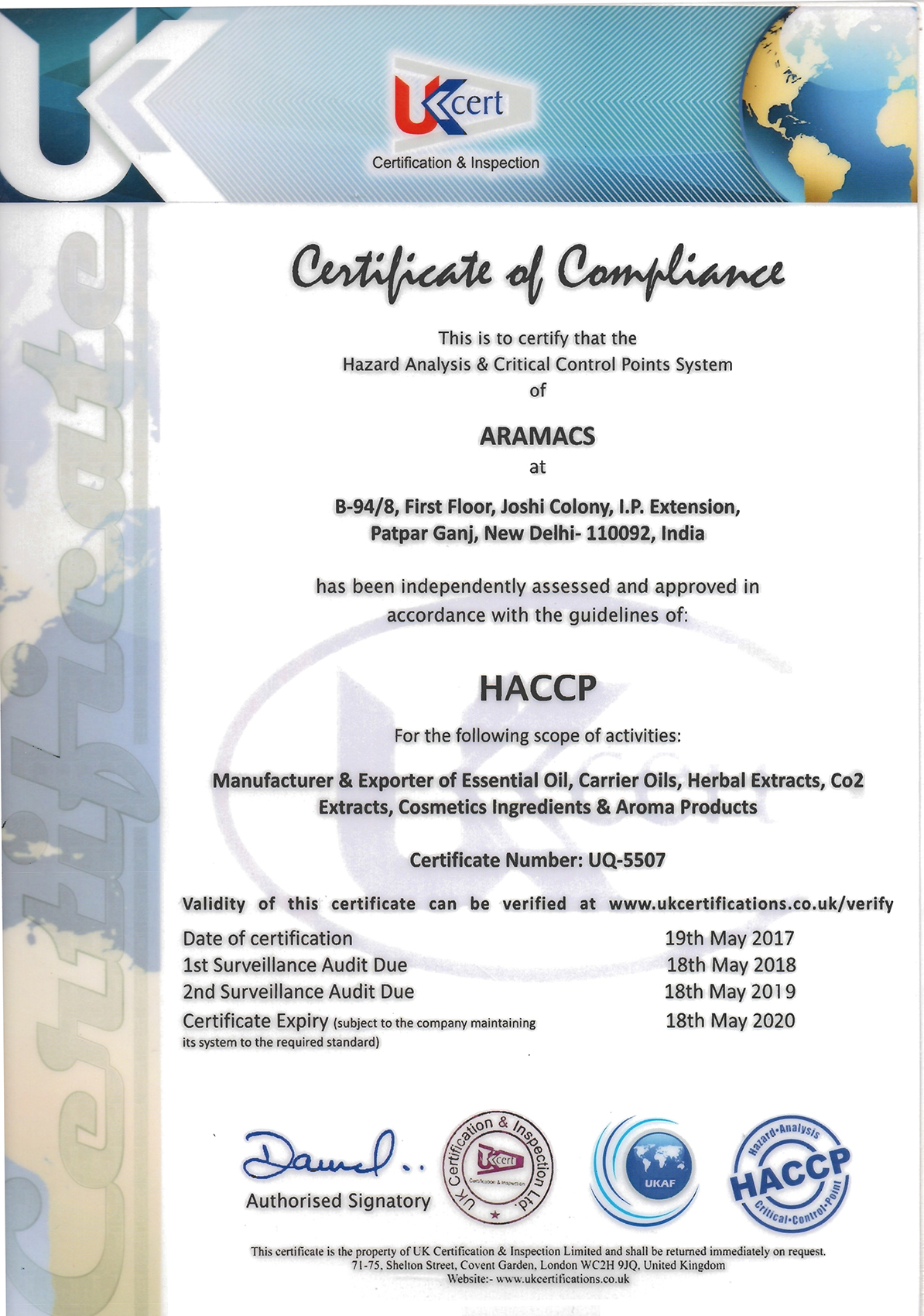

We Aramacs are manufacturers of High quality supercritical extracts from India. Supercritical extracts are obtained with the help of Liquid CO2 gas at a certain temperature and pressure, known as supercritical point, It plays a vital role in the extraction process while extracting quality essential oil. A good thing about this CO2 is that in comparison with other methods of chemical extraction, it is completely non toxic in nature. The impact it has on the environment nill.

CO2 extraction takes place at quite a low temperature. Volatile and non volatile molecules are present various herbs, barks and roots are extracted in this process. The heat does not damage or alter the compounds in any way. On the final product, it does not leave any trace of itself as at normal atmospheric pressure, carbon dioxide is just like gas, which escapes the extracts automatically.

The method is quite expensive since the equipment used itself is not very cheap. Thus compounds generated in the process, also prove to be little expensive and ingredients obtained are more effective and better than regular extracts.

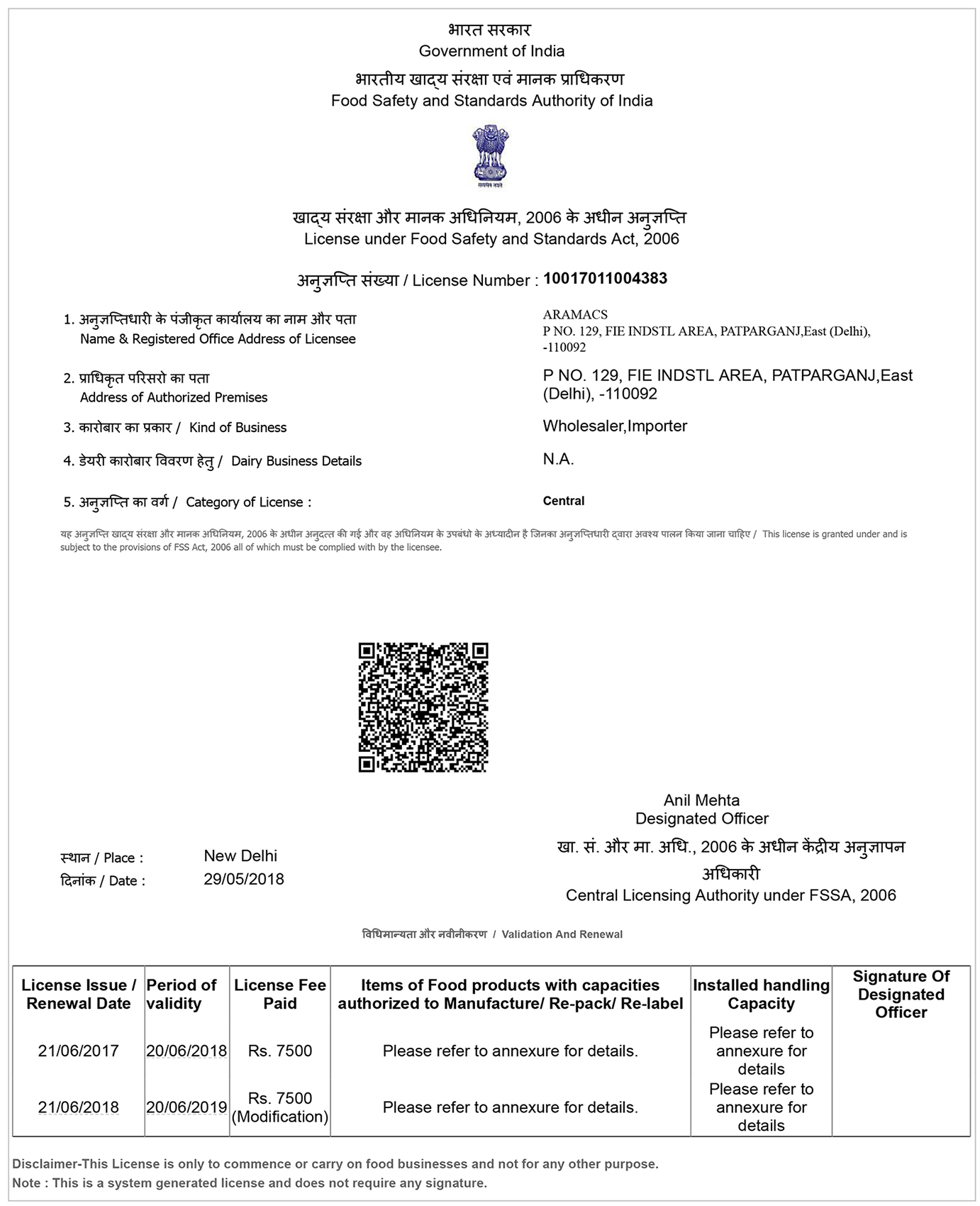

Traditional methods of extraction have been used since years. However there are several advantages to supercritical CO2 oil extraction methods. A good aspect about CO2 is it is termed as GRAS – Generally Regarded As Safe by the Food and Drug Administration authorities.

The spent material can be used again as it is free of any residual contaminates. Carbon dioxide is non-flammable in nature and does not need any costly facilities that are explosion proof. Another positive attribute about carbon dioxide is that it is cold. Oil extractions can be done at temperatures native to the botanical material. This helps minimize both the extracted oil and plant material’s thermal degradation. Carbon dioxide’s solvency power is easy to adjust.

All that is needed is to decrease or increase the temperature or pressure. CO2 is useful in creating extracts that are unique in nature and have waxes and oils in desirable levels. Several industries use CO2 as it is readily available and is cheap. Out of the total carbon dioxide used in the extraction process, more than 90% of carbon dioxide is also recovered subsequently and re-circulated by the CO2 oil extraction systems.

Call IND

Call IND  Call USA

Call USA